SUSTAINABILITY

Green Performing Extrusion Blow Moulding Machines

Green Performing best practices

We design machines that minimize energy consumption, reduce waste and optimize material usage

Our solutions help manufacturers achieve their environmental goals while maintaining superior production efficiency and quality standards.

2025 -> 2030

vision journey to best sustainable impactMinimum kwh/kg

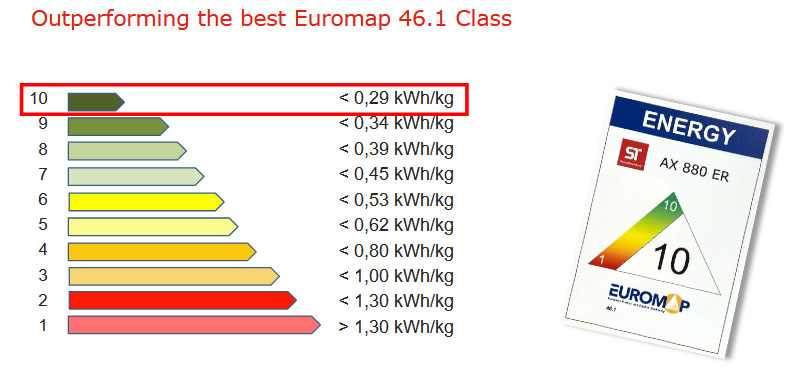

Best Euromap 46.1 Class 10

Increased OEE

Reduced rejects (NOK Parts)

STONE

RAW MATERIAL COST SAVINGS

- The superior weight control technology translates directly into measurable cost savings and improved production efficiency for your operation.

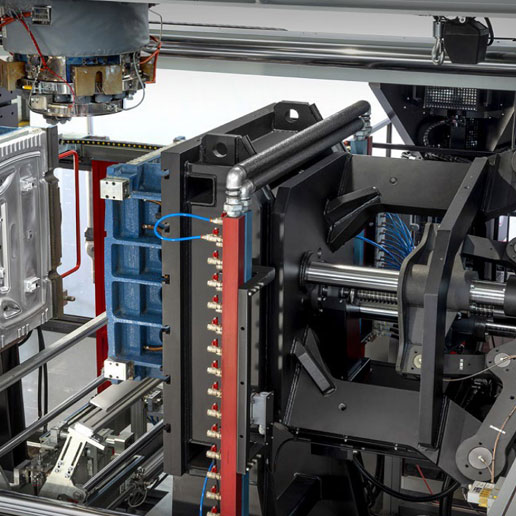

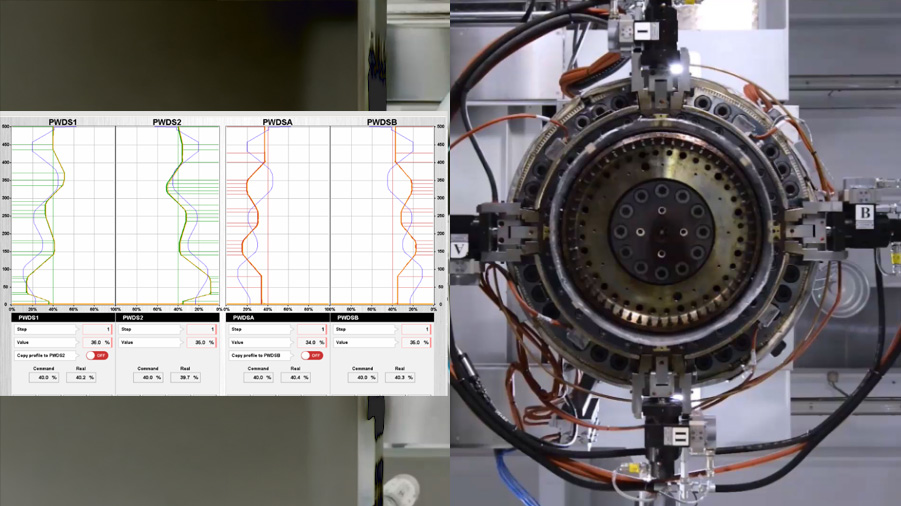

- 500 points resolution of all parison thickness profile.

- Wide usage of PWDS systems (axial and radial dynamic control of the parison thickness)

- Less material waste and lower production costs

- Estimated material savings of 4% compared to low-cost machines

Reducing the Raw Material consumption

- tighter weight distribution ensures uniform product quality

- minimizes rejection rates and rework requirements

- more constant production output

- weight maintenance between MIN and MAX acceptance limits

- significantly better performance compared to low-cost machines

- reduces the risk of overweight parts that waste material

- lower scrap rates

- decreased quality control interventions

- improved end-product consistency

- reducing the rejects

- process monitoring

- reaction to process value variation

STONE POWERED BY ST

LOW ENERGY CONSUMPTION

BEST ST HERITAGE AND KNOW-HOW APPLICABLE ON STONE MACHINES ON REQUEST

The STONE machines could be equipped on request by the ST typical top features to increase power savings:

- Severe heat insulation of the plasticizing section

- Usage of synchronous reluctancy motors for all the extruders

- Variable speed hydraulic pumps (for the hydraulic machines)

- All-electric clamping units - toggle type

“Adiabatic” extruders (without cooling fans) with special screw and barrel configuration and design enabling the lowest power need to run at the best output.

Our special extruders screw and barrel design allows:

- Minimum shear effect

- No cooling fans

- 90% less heat dissipation

- Very low power consumption

Sustainability